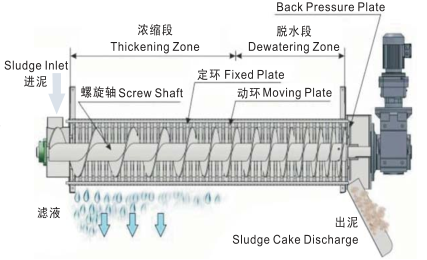

Structural principle

The main body of the dehydrator is a filtering device which is composed of a fixed ring and a swimming ring, and a spiral shaft runs through it. The small movable filter gap formed between the fixed ring and the moving ring is used to filter the filtrate. The inner cavity formed by the spiral shaft and the ring plate is filled with flocculated particles, which turns to the back pressure plate at the end. In the dynamic process, the mud cake is transported and extruded. The spiral shaft is rotated and pushed to continuously drive the moving ring to move up, down, left and right to clean the filter seam to prevent blockage.

Applicable industries

It is suitable for municipal sewage, domestic sewage, food, beverage, chemical industry, leather, welding materials, papermaking, printing and dyeing, pharmacy, electroplating, oil field, coal mine, wine making, animal husbandry, kitchen wastewater, water plant, power plant, steel plant and other industries.

Technical advantages

1. It is suitable for dewatering of high and low concentration sludge. When the sludge with low concentration (2000mg / L) is dewatered, there is no need to build thickening tank and storage tank, which can reduce the construction cost, release phosphorus and produce anaerobic odor.

2. It is not blocked, reduces the water consumption, saves the water cost and reduces the internal circulation burden caused by the return of cleaning water.

3. The electric control cabinet, flocculation mixing tank and dehydration main body are integrated to reduce the floor area, and the installation is simple and convenient.

4. The dehydrator is basically in closed operation, and the treatment is stable and timely, so that the odor on site is reduced to low, and the working environment of workers is improved.

5. Realize automatic 24-hour operation, less labor intensity of operation workers.

6. The speed of screw shaft is low, 2-3 revolutions per minute, low power consumption, and there is no vibration and noise on site.

7. Almost all the body is made of stainless steel, which can greatly extend the service life. The replacement parts only have spiral shaft and floating ring, which has a long service life.

8. The daily maintenance time is short and the maintenance work is simple.

Filter cloth width: 500mm-2000mm

Sludge treatment capacity: 2m3 / h-312m3 / h

Main material: SUS304

Application: all kinds of industrial wastewater sludge dewatering treatment slaughterhouse sludge dewatering treatment urban sewage, water and fertilizer, water treatment plant sludge dehydration treatment, food, chemical industry, mining and other industrial processes in solid-liquid separation treatment

Features: the main structure is made of stainless steel SUS304

The filter cloth imported from Europe and America has a long service life.

Frequency conversion speed regulation, high stability, good operability.

Chemical conditioning reaction system: sludge and polymer are injected into the bottom of the system. After sufficient time of coagulation and mixing, floc is formed and overflowed to the sludge water separation and screening thickening tank in the front section. The tank body group is installed on the machine, and the open type is adopted to facilitate the observation of conditioning condition and polymer consumption.

Filter cloth tension system and serpentine correction device: the tension of filter cloth can be adjusted according to the actual demand, and the special pressure stabilizing device can ensure the low moisture content of mud cake. The tension system can be automatically switched to use. When the machine is stopped, the cylinder retracts and the filter cloth is automatically relaxed, so as to reduce the fatigue of the filter cloth due to long-term tension, protect and extend the service life of the filter cloth. According to the principle of air pressure induction valve and cylinder displacement control, the filter cloth can be operated within a certain range. The induction actuation is stable, there is no leakage, and the safety is high.

Centralized sludge distribution device: guide the sludge mass to be concentrated in the center of filter cloth, and adjust the width and width of distribution sludge mass according to the expansion characteristics of sludge pressed to prevent side leakage.